How Often Should Filter Cartridges Be Replaced?

2025-09-09 Eternalwater Determining when to replace pleated microporous membrane filter cartridges is crucial for ensuring filtration efficiency, product quality, and production safety. There is no fixed schedule for replacement, as the cycle depends on various factors such as the properties of the filtered fluid, contaminant levels,, operating pressure, flow rate requirements, and more.Below are the key indicators and operational methods to determine when a filter cartridge needs replacement. You can make a comprehensive judgment based on the actual situation:

Primary Judgment Criteria (Gold Standard)

1.Increase in Differential Pressure (ΔP) – The Most Critical and Objective Indicator

Differential pressure refers to the difference between the inlet pressure and outlet pressure of the filter cartridge. A new filter cartridge has a very low differential pressure (known as the initial differential pressure). As filtration proceeds, contaminants are captured, blocking the pores of the filter membrane and increasing flow resistance, leading to a continuous rise in differential pressure.

①Reaching the Maximum Allowable Differential Pressure:

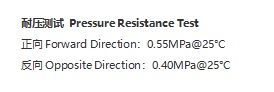

Each filter cartridge has a maximum allowable differential pressure (typically between 0.3-0.5 MPa) specified by the manufacturer. Once the operating differential pressure approaches or reaches this value, the cartridge must be replaced. Continued use may lead to structural damage (e.g., collapse of the pleated membrane), puncturing, and complete loss of filtration efficiency.

②Differential pressure doublin:

If no specific value is defined, a general rule of thumb is to consider replacement when the differential pressure increases to 2-3 times the initial value. For example, if a new cartridge has an initial differential pressure of 0.05 MPa, once it rises to 0.1–0.15 MPa, filtration efficiency has significantly declined, and operation becomes economically inefficient.

③Monitoring Method:

Install pressure gauges at the inlet and outlet of the filtration system. This allows operators to easily read the real-time differential pressure value.

In systems operating under constant pressure (the most common mode), as the filter cartridge becomes clogged, the increase in differential pressure leads to a gradual decline in filtration flow rate.

● Judgment Criteria:

If the flow rate drops to a level that can no longer meet the requirements of the production process, the filter cartridge must be replaced—even if the differential pressure has not yet reached the maximum allowable value.For example, a filtration task that originally required one hour to complete may now take three hours due to the reduced flow rate, severely impacting production efficiency.

Auxiliary Judgment Criteria (Must be used in conjunction with primary criteria)

1.Changes in Filtered Product Quality

This approach deduces the filtration status from the end result and serves as the final quality safeguard.

● Judgment Criteria:

Conduct quality inspection on the filtered products

If any of the above conditions occur, it indicates that the filter cartridge may have failed (e.g., due to damage or breach after complete clogging). It must be replaced immediately, and the already filtered product should be isolated and evaluated.

2.Changes in Filter Cartridge Appearance (Post-Removal Inspection)

When replacing a filter cartridge, a visual inspection of the used one can be conducted. This helps assess the filtration status and provides reference for determining the next replacement cycle.

● Judgment Criteria:

Color and Physical Form: The cartridge is deeply discolored by contaminants (e.g., oils, rust, pigments), or adsorbed contaminants have clumped and hardened.

Integrity Test Failure:

For applications requiring high absolute precision (e.g., sterile filtration), integrity testing—such as bubble point or diffusion flow tests—must be performed before and after sterilization or before and after use. If the test fails, it confirms that the cartridge is defective or damaged. It must not be used under any circumstances and should be replaced immediately.

Summary and Operational Suggestion

To systematically manage filter cartridge replacement, the following procedures are recommended:

1.Establish a Baseline: Record the initial differential pressure (ΔP) and flow rate of a new filter cartridge.

2.Real-Time Monitoring: During filtration, closely monitor the trend of differential pressure (ΔP) changes. This is the most direct and reliable online judgment method

3.Set Warning Values: on the maximum differential pressure provided by the manufacturer, set a replacement warning threshold (e.g., 80% of the maximum allowable differential pressure).

4.Quality Sampling:Regularly sample and test the filtered product to verify filtration performance.

5.Final Confirmation:If necessary, perform integrity testing on replaced cartridges to confirm their final condition and document the reason for disposal.

In simple terms, remember this order of priority:

First, monitor differential pressure. Replace immediately if the limit is exceeded.

Next, monitor flow rate. Replace promptly if the flow is insufficient and impacts production.

Finally, monitor quality. Replace and trace previous batches if product quality fails to meet standards.

By adopting this multi-dimensional, data-driven approach to determining filter cartridge replacement timing, you can ensure filtration quality while maximizing service life and achieving optimal cost-effectiveness.

Latest News

Read more

- Industry Application

- Life Sciences

- water treatment

- Industrial Filtration

- Food & Beverage

- Microelectronics

- Laboratory

- New energy battery

- Contact Us

- [email protected]

- +86-571-87022016

- +86-571-87293027

- +8613675899519

- Subscribe for Join Us!

- Join us and get detail information,technical parameter and new products etc.

CopyRight © Hangzhou Eternalwater Filtration Equipment Co., Ltd. 2002-2025

- [email protected]

- Jenny wu

- +8613675899519

- +86(571) 87022016

EN

EN  ES

ES AR

AR JP

JP CN

CN