Home News Technical articles The Importance of Electrode Slurry Filtration in Lithium Battery Manufacturing Processes

The Importance of Electrode Slurry Filtration in Lithium Battery Manufacturing Processes

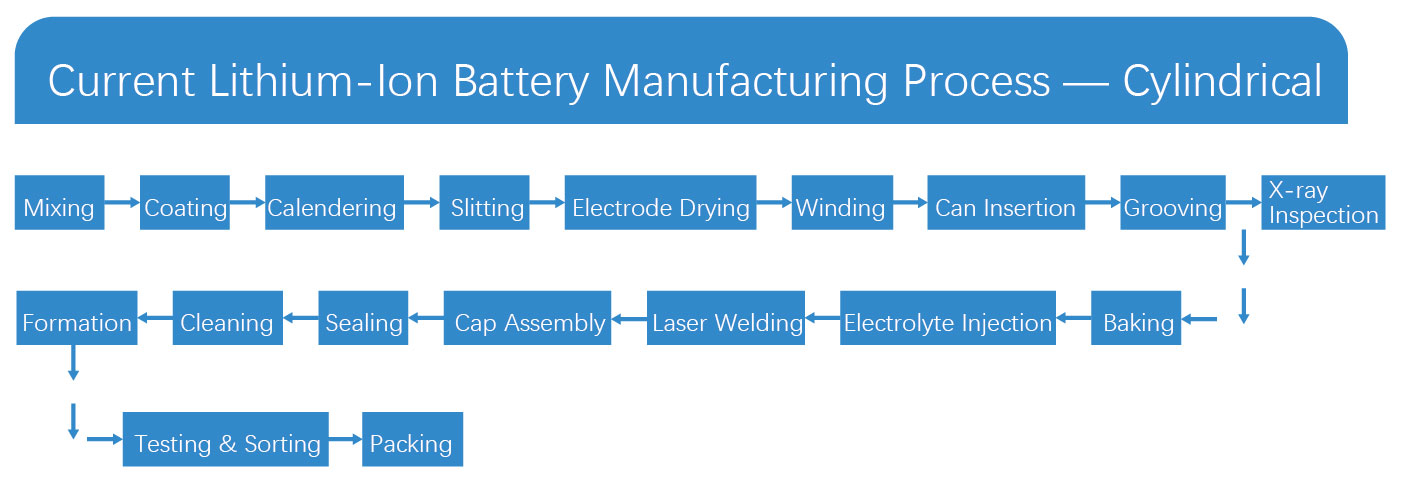

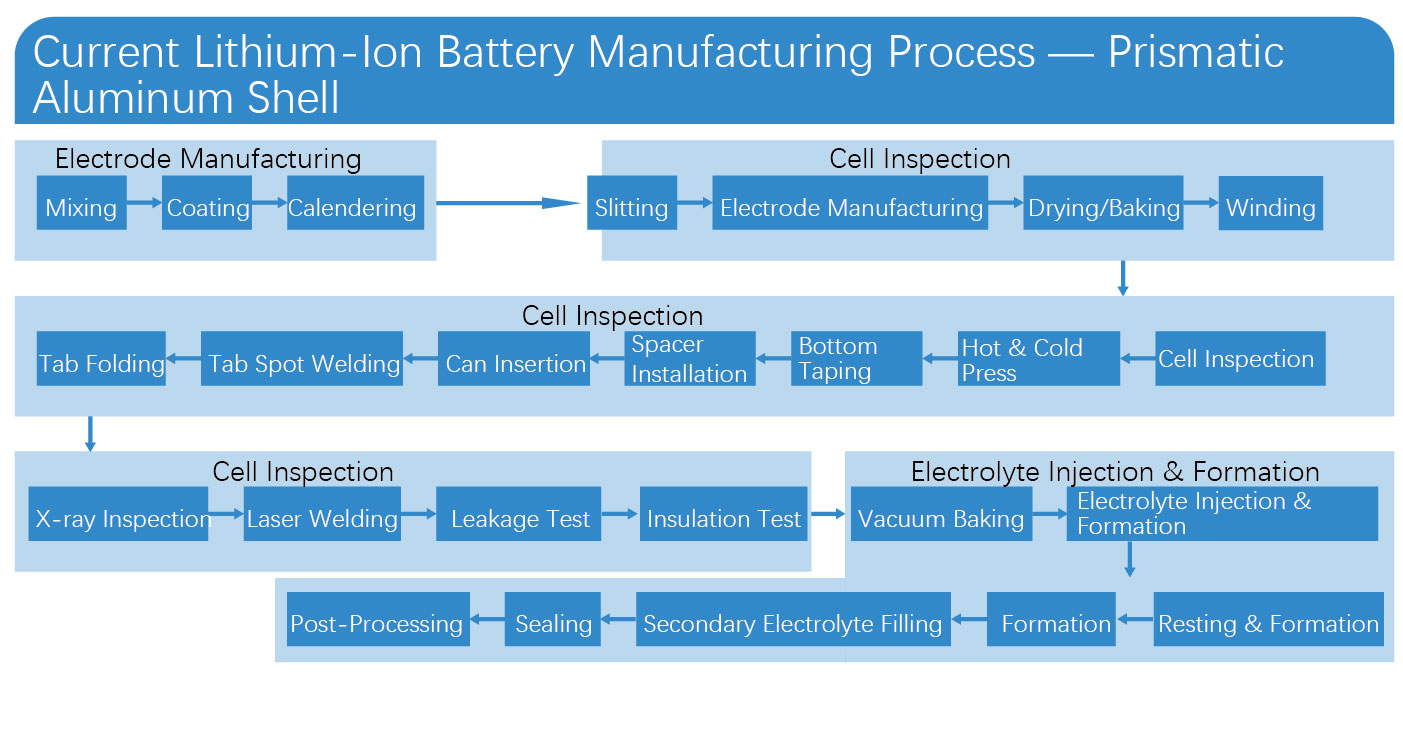

2025-12-05 AdminThe rapid development of new energy vehicles has driven substantial growth in the power battery industry.

By filtering the slurry, large particles and deformable contaminants can be removed, which helps reduce battery defects, enables the production of consistent high-quality slurry, and ensures the stability of cathode/anode electrode manufacturing and coating processes.

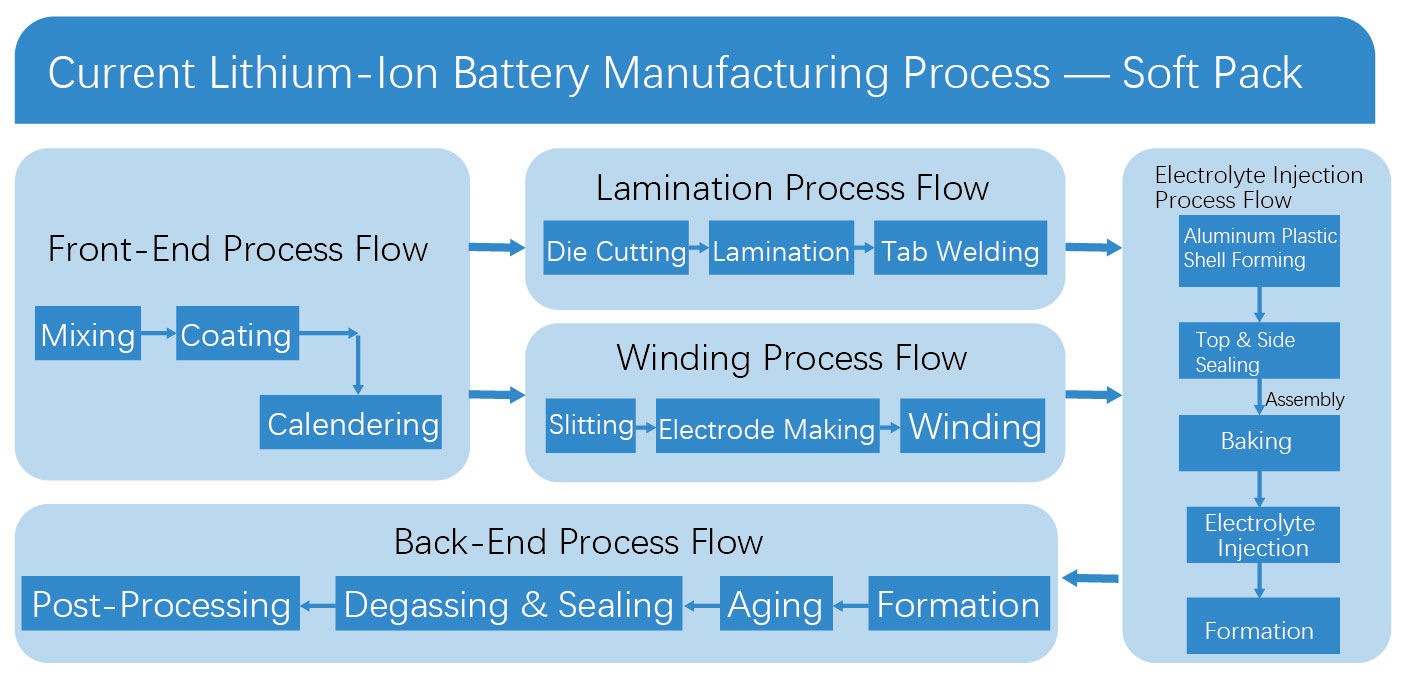

A lithium-ion battery cell consists of an anode, cathode, electrolyte, separator, and other components. The working principle of a lithium-ion battery can be simply described as: lithium ions move between the anode and cathode, thereby carrying and storing electrons during the charging and discharging processes.

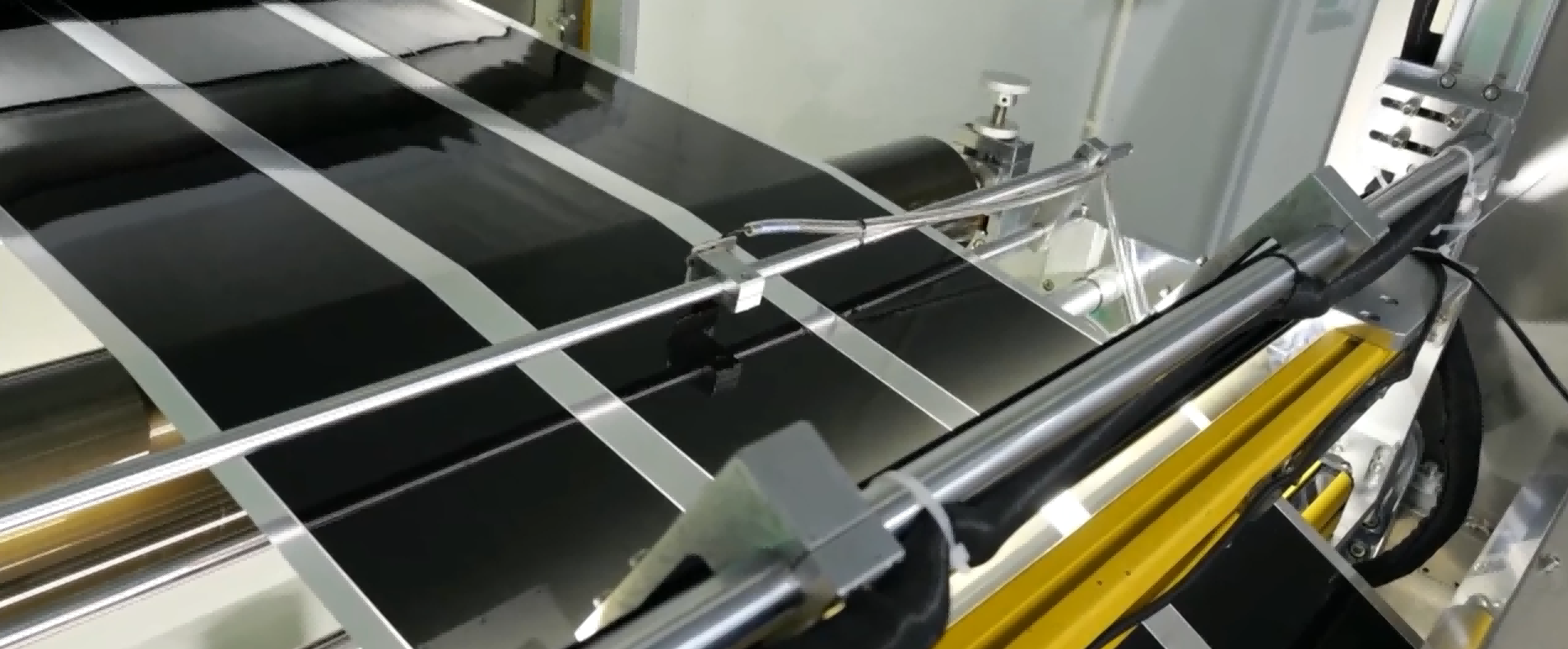

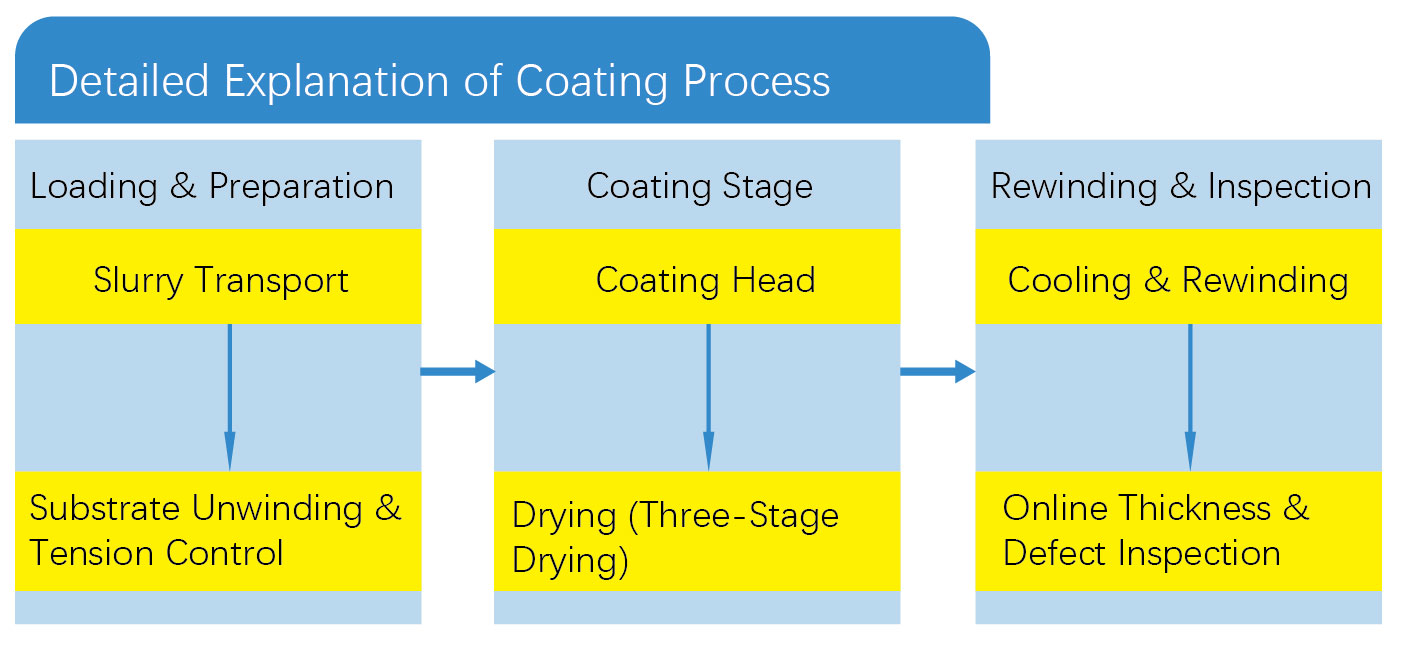

During the manufacturing process, coating is a critical step in battery cell production. Uniformly mixed slurry (a mixture of active materials, conductive agents, binders, etc.) is evenly, continuously, and stably applied onto metal current collectors (aluminum foil for the positive electrode and copper foil for the negative electrode), and the solvent is then dried to form electrode sheets with consistent thickness and no defects.

The coating process directly determines the capacity, consistency, safety, and lifespan of the battery. It can be said that the quality of coating is the cornerstone of high-performance batteries.

|

|

|

|

Common Coating Defects and Their Causes

1.Large particles present in the slurry:Impurities or damage on the die head or blade;large particles in the slurry.

2.Uneven Thickness/Wavy Edges: Uneven gap in the die head; fluctuations in slurry supply pressure; improper tension control.

3.White Spots/Exposed Foil:Poor wettability of the slurry;oil stains on the substrate surface;air bubbles in the slurry

4.Orange Peel Texture:Drying too quickly, leading to poor surface fluidity of the slurry

5.Air Bubbles:Incomplete degassing of the slurry; rapid solvent vaporization during the drying process

6.Adhesion:Electrode sheets sticking together after winding, which is caused by incomplete drying with excessive residual solvent and excessive winding tension:

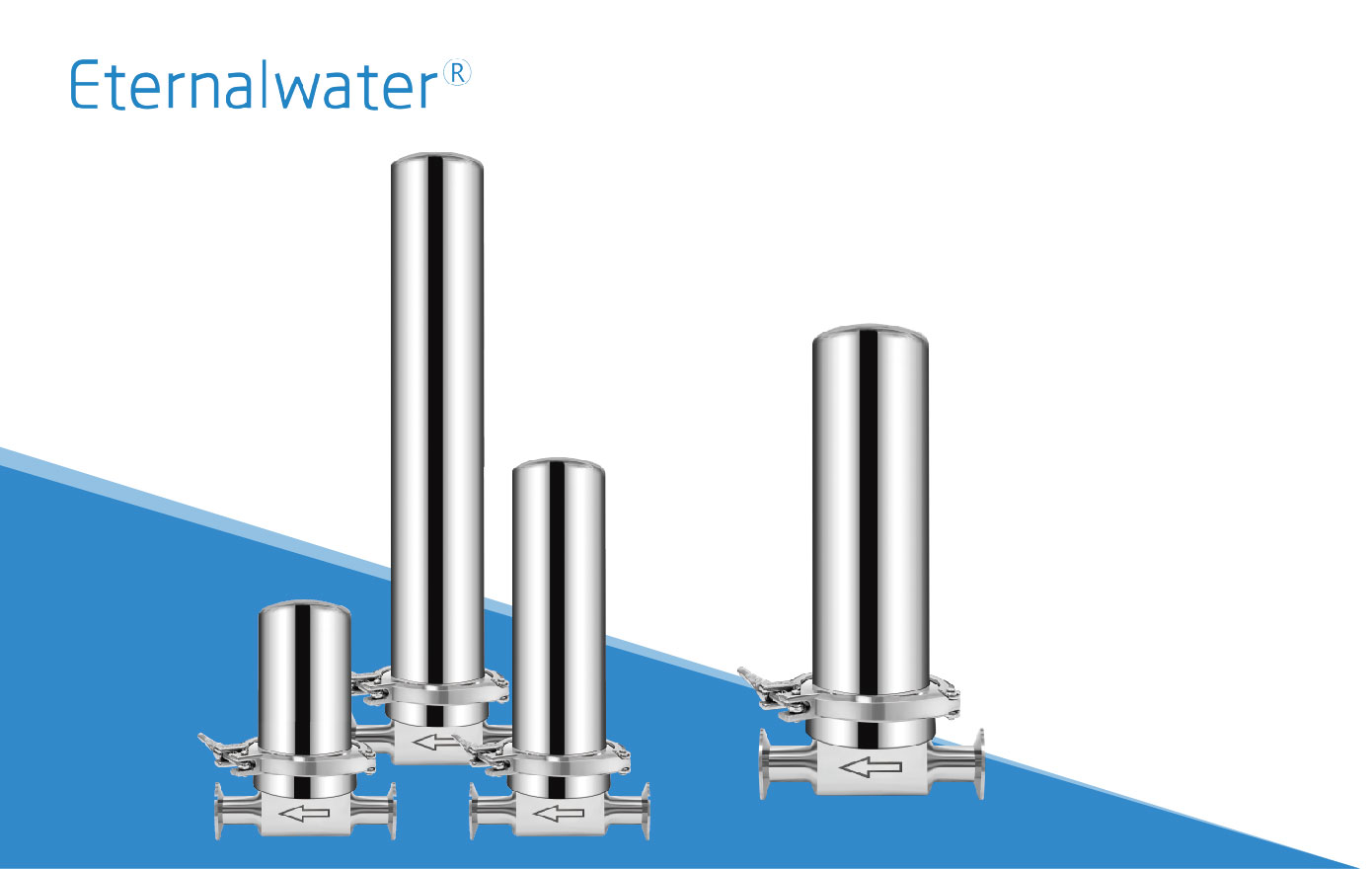

The Eternalwater® series slurry filters are suitable for high-viscosity slurry filtration. They can retain oversized particles while allowing smaller effective components to pass through, offering excellent grading performance and efficient particle removal capabilities.

|

|

|

|

|

|

|

|

The slurry filter adopts a unique structural design, with the inner core tightly fitted to the PP housing, minimizing the gap between them to effectively reduce liquid loss. Since the liquid remains inside the encapsulated filter cartridge, there is no need to clean the outer housing, thus reducing processing costs. Additionally, the filter incorporates a unique check valve design with splash-proof functionality, preventing operators from being exposed to hazardous materials. This ensures maximum safety and environmental protection throughout the filtration process.

To reduce the mixing cycle time, a more economical and effective approach is to filter out 0.1% of the unmixed particles. This can be achieved using a single micron-precision filter, a gradient pore-size structured filter, or multiple filters with pore sizes decreasing from upstream to downstream to optimize filtration. The optimization of the filtration system depends on the particle size and distribution of the active battery materials. Providing high-quality slurry to the coating nozzle requires a monitoring system and tracking the pressure drop across each filter, which ensures sufficient slurry supply to the die head. In most cases, a two-stage or three-stage filter combination can provide an optimized filtration process, thereby extending filter life, reducing filter replacement frequency, and lowering overall operating costs.

- Industry Application

- Life Sciences

- water treatment

- Industrial Filtration

- Food & Beverage

- Microelectronics

- Laboratory

- New energy battery

- Contact Us

- [email protected]

- +86-571-87022016

- +86-571-87293027

- +8613675899519

- Subscribe for Join Us!

- Join us and get detail information,technical parameter and new products etc.

- [email protected]

- Jenny wu

- +8613675899519

- +86(571) 87022016

EN

EN  ES

ES AR

AR JP

JP CN

CN