Home News Company News Seven-Core Slurry Capsule Filter, Meeting High-Speed, High-Flow Filtration

Seven-Core Slurry Capsule Filter, Meeting High-Speed, High-Flow Filtration

2025-12-12 AdminAs a core industrial filtration device, the slurry filter achieves efficient solid-liquid separation through innovative structural design and plays a crucial role in fields such as lithium battery manufacturing, semiconductor processing, and chemical production.

In the electrode manufacturing for lithium-ion batteries, the cathode slurry consists of binder, conductive agent, cathode material, etc., while the anode slurry comprises binder, graphite carbon powder, etc. The preparation of both cathode and anode slurries involves a series of processes including mixing, dissolving, and dispersing between liquid-liquid and liquid-solid materials. Therefore, the mixing and dispersion of the electrode material slurries are critical in lithium-ion battery production. The quality of slurry dispersion directly affects the subsequent production quality and the performance of the final battery products.

|

|

|

Cathode (Aluminum Foil) |

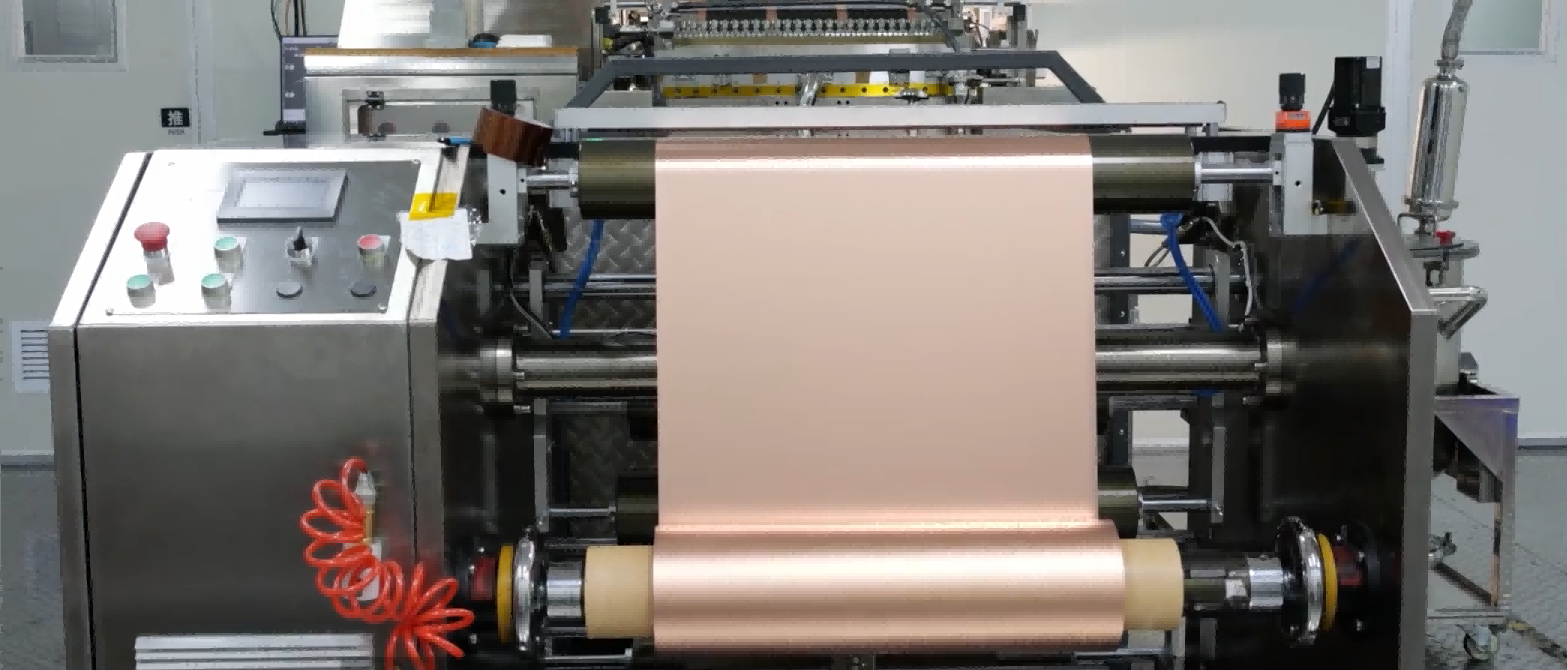

Anode (Copper Foil) |

Product Introduction:

The Seven-Core Slurry Capsule Filter is a high-efficiency filter featuring an advanced multi-core design, specifically developed for industrial and professional applications requiring high flow rates. With a parallel configuration of seven independent filter cores, this product significantly increases filtration throughput while maintaining excellent filtration precision, making it an ideal choice for handling large-volume liquids. Currently available in two standard sizes, 10-inch and 20-inch, it caters to application needs of different scales. It is an integrated filter cartridge designed specifically for slurry filtration, with its high-flow design capable of adapting to high-speed, wide-web production lines.

Product Features:

1.Designed for high-speed, wide-web, high-flow slurry coating filtration.

2.Easy replacement, less residue, long service life, reduces downtime for cartridge replacement, and improves production efficiency.

3.Configurable for liquid drainage, enabling slurry recovery and reuse.

Product Applications:

1.Filtration during battery slurry preparation.

2.Slurry filtration prior to cathode and anode coating.

3. Scenarios involving high viscosity, wide web width, and high pressure.

Why Choose Our Seven-Core Capsule Filter?

1.Longer filter cartridge life reduces replacement frequency.

2.High-flow design reduces the number of equipment investments.

3.Low operating pressure drop lowers energy consumption costs.

4.Free filtration solution consulting services.

5.Rapidly responsive after-sales support.

6. Ample filter cartridge inventory ensures timely supply.

Whether for lithium battery filtration, semiconductor processing, chemical production, or other applications, our 10-inch and 20-inch Seven-Core Slurry Capsule Filters provide reliable, efficient, and cost-effective filtration solutions. Their unique multi-core design and exceptional filtration performance will help you improve product quality, reduce production costs, and ensure process stability.

Welcome to contact our sales team (86-571-87022016) for a customized filtration solution tailored to your needs!

Product Specifications and Parameters:

|

Housing Material |

Polypropylene (PP) |

|

Filter Membrane Material |

Polypropylene (PP) |

|

Number of Inner Cores |

7 |

|

Inner Core Length |

10 inch, 20 inch |

|

Sealing Ring |

EPDM |

|

Maximum Operating Temperature |

80°C |

|

Outer Diameter |

212.5 mm |

|

Vent Valve Thread Size |

R 1/4 |

|

Check Valve Material |

Seal = PP / Spring = SUS304 |

|

Inner Core Structure |

Wound, Pleated |

|

Maximum Operating Pressure |

0.7 MPa |

- Industry Application

- Life Sciences

- water treatment

- Industrial Filtration

- Food & Beverage

- Microelectronics

- Laboratory

- New energy battery

- Contact Us

- [email protected]

- +86-571-87022016

- +86-571-87293027

- +8613675899519

- Subscribe for Join Us!

- Join us and get detail information,technical parameter and new products etc.

- [email protected]

- Jenny wu

- +8613675899519

- +86(571) 87022016

EN

EN  ES

ES AR

AR JP

JP CN

CN