Lithium battery slurry filtration

2024-04-03 Eternalwater

"Focus on dual carbon goals and lead green development"

As the whole society pays attention to "carbon peak and carbon neutrality" and the implementation of the "14th Five-Year Plan", the new energy industry will usher in broader development opportunities.

The rapid growth of electrochemical energy storage and power batteries worldwide has driven a surge in demand for lithium batteries. The main downstream of lithium batteries include power batteries, energy storage batteries, consumer electronics batteries, etc. Driven by the common vision of global long-term sustainable development and carbon neutrality, the world is experiencing an energy revolution, and the demand for power batteries and energy storage batteries is surging.

Market demand and technological innovation have promoted the continuous updating of lithium battery technology, and have also put forward higher requirements for filtration, an important part of battery assembly, among which slurry filtration is particularly important.

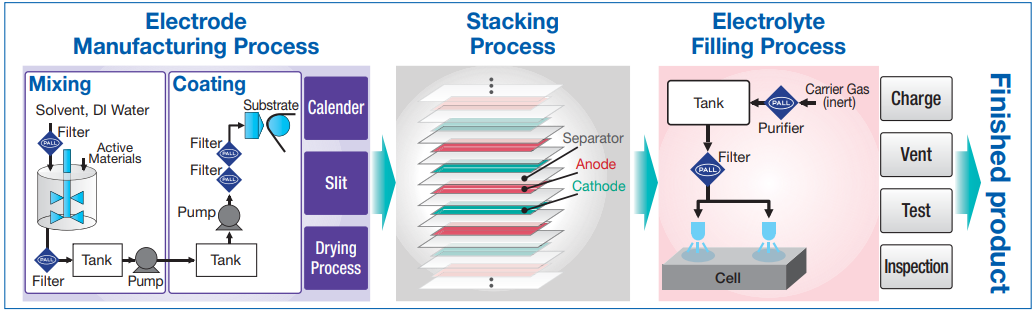

Battery assembly process (the picture above is from PALL Company)

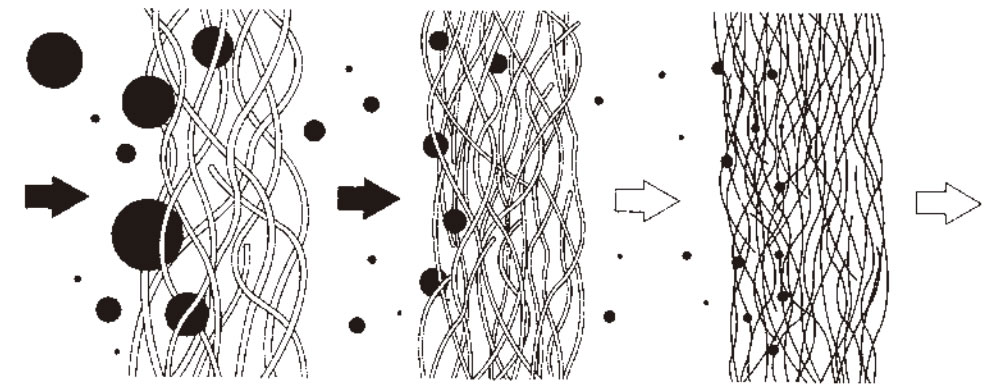

The ideal electrode slurry is a suspension that is evenly dispersed and has high stability. Since substances with different polarities are mixed with each other during the homogenization process, there will inevitably be agglomeration of particles, which will affect the coating quality of the slurry and result in poor battery consistency. The existence of defective pole pieces such as particle scratches affects the production efficiency during the electrode production process, the qualification rate of the pole plates and the safety of battery use. Therefore, the slurry needs to be filtered before coating. The choice of filter is crucial when slurry filtration. The filter must allow the desired particles to pass while retaining oversized particles.

The EH series capsule filter adopts a unique structural design. The inner core is close to the PP shell with a very small gap, which effectively reduces liquid loss. Since the liquid will remain within the encapsulated filter element, there is no need to clean the housing reducing disposal costs. It also features a unique check valve design that is splash-resistant to prevent operator exposure to hazardous materials. It provides the greatest guarantee for a safe and environmentally friendly filtration process.

Product Characteristics

The filter cartridge can be replaced with a simple operation ;Suitable for high viscosity liquid filtration ;

Keep the production environment clean and reduce environmental pollution ;

The gap between capsule and filter is small, minimizing slurry residue ;

There is no need to clean the stainless steel filter as the liquid will remain inside the encapsulated filter cartridge;

pleated filter cartridge factory

- Industry Application

- Life Sciences

- water treatment

- Industrial Filtration

- Food & Beverage

- Microelectronics

- Laboratory

- New energy battery

- Contact Us

- [email protected]

- +86-571-87022016

- +86-571-87293027

- +8613675899519

- Subscribe for Join Us!

- Join us and get detail information,technical parameter and new products etc.

- [email protected]

- Jenny wu

- +8613675899519

- +86(571) 87022016

EN

EN  ES

ES AR

AR JP

JP CN

CN