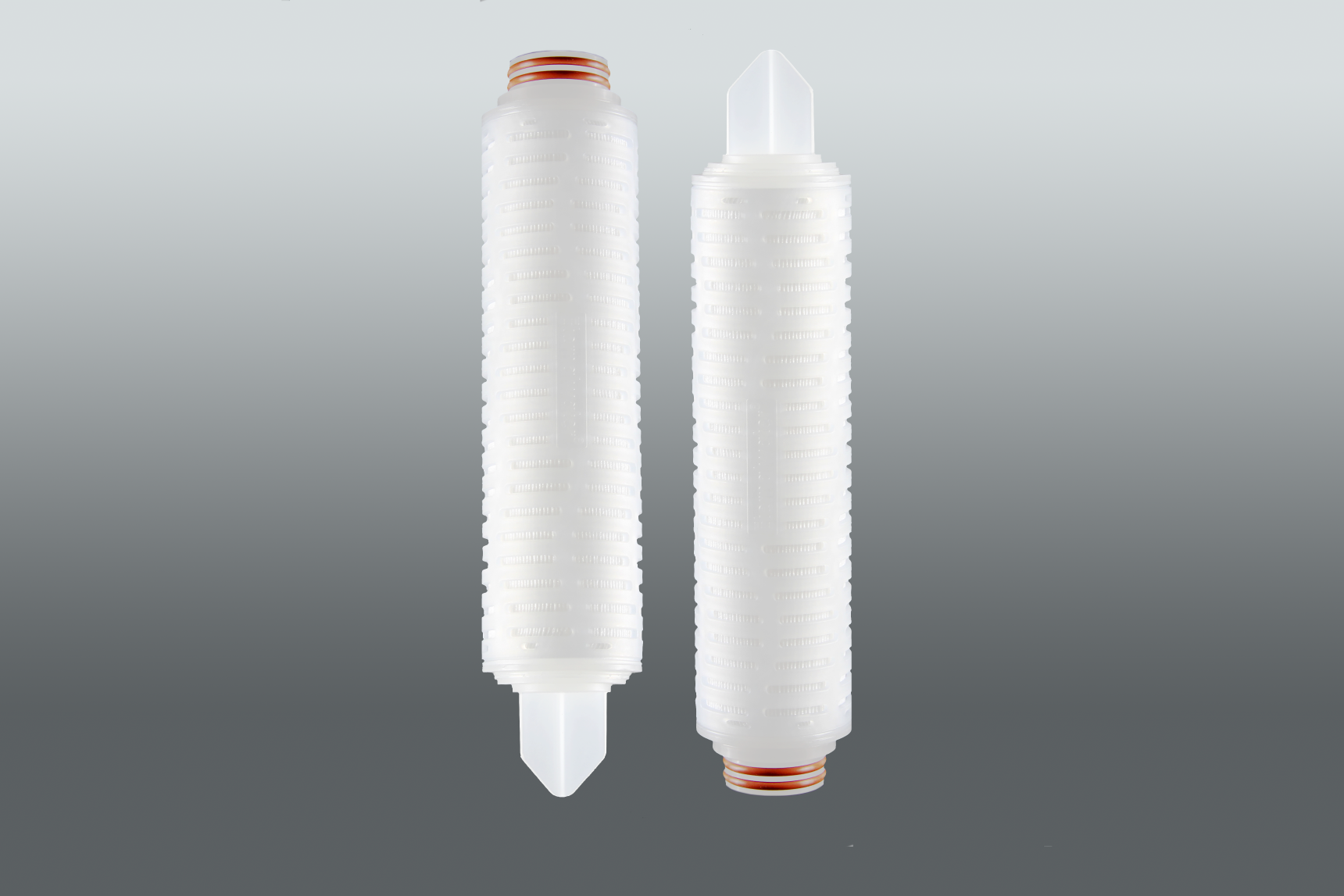

PTFE EKT Series

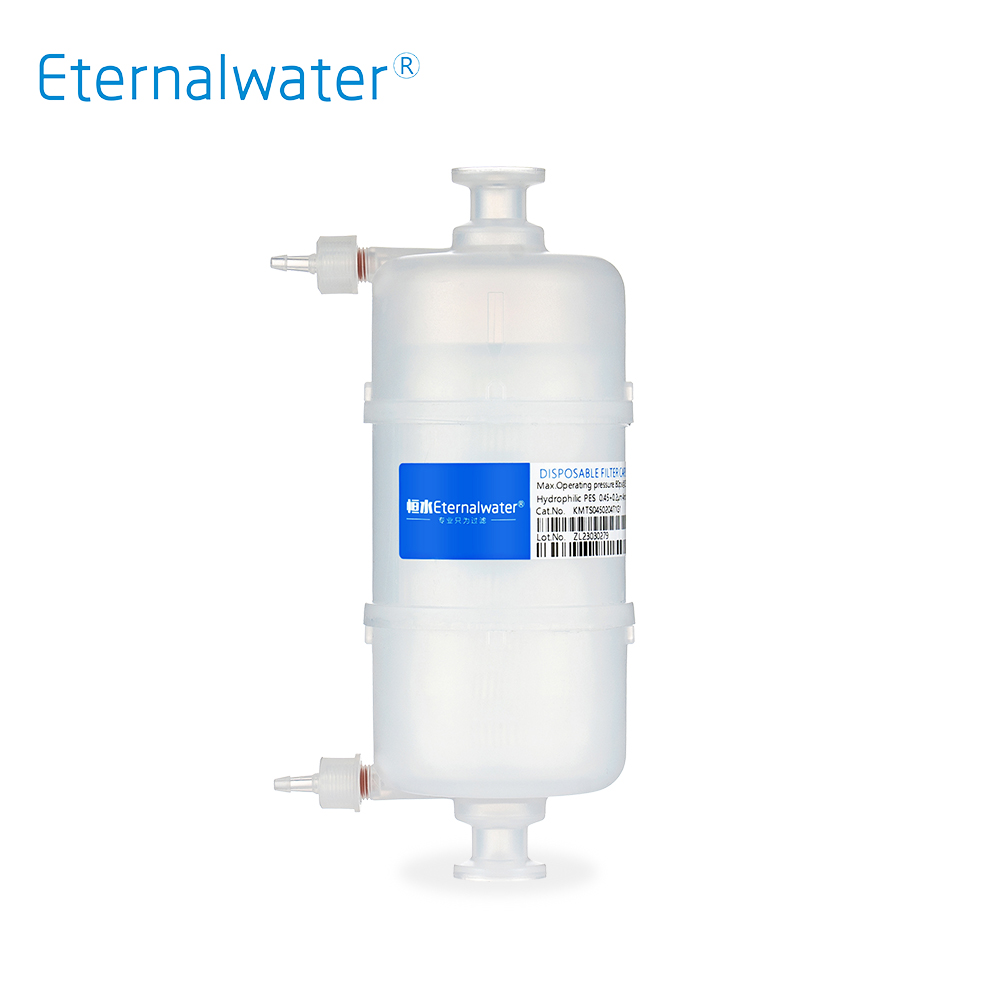

It is suitable for gas sterilization and adopts imported hydrophobic PTFE membrane, which has high flux and high sterilization efficiency. The filter element has good heat resistance and can operate steam sterilization for over 150 times.The integrity test before delivery ensures the high quality of products.

- Product features

- High flow rate, long life, high sterilization efficiency Absolute aperture ensures effective filtration Each filter element passes the integrity test

- Industry Application

- Electronic industry: Ultra-purification filtration for precision mechanical gas, compressed gas filtration, fermentation gas Pharmaceutical industry: sterilization and filtration, aseptic packaging machine filtration, filtration of tank type sterile respirator Food industry:sterilization and filtration, aseptic packaging machine filtration

- DOWNLOAD

- INQUIRY NOW

PRODUCT DESCRIPTION

- Operating conditions

- Operating temperature: ≤95℃

- Maximum pressure difference that can withstand: 4bar (21℃)/2.4bar (80℃)

- Sterilization method: 121℃/30min steam sterilization

- Material structure

-

Filter material: Imported PTFE membrane

- Inner core: high temperature resistant PP (lined with stainless steel)

- shell: high temperature resistant PP

- End cap: high temperature resistant PP (lined with stainless steel)

- Sealing technology: hot melt welding

- Gasket/O-ring: Silicone rubber, EPDM, fluororubber

- Filter element size

- external diameter: (68mm)

- length: 5〞、10 〞、20 〞、30〞、40〞

Ordering Information

related products

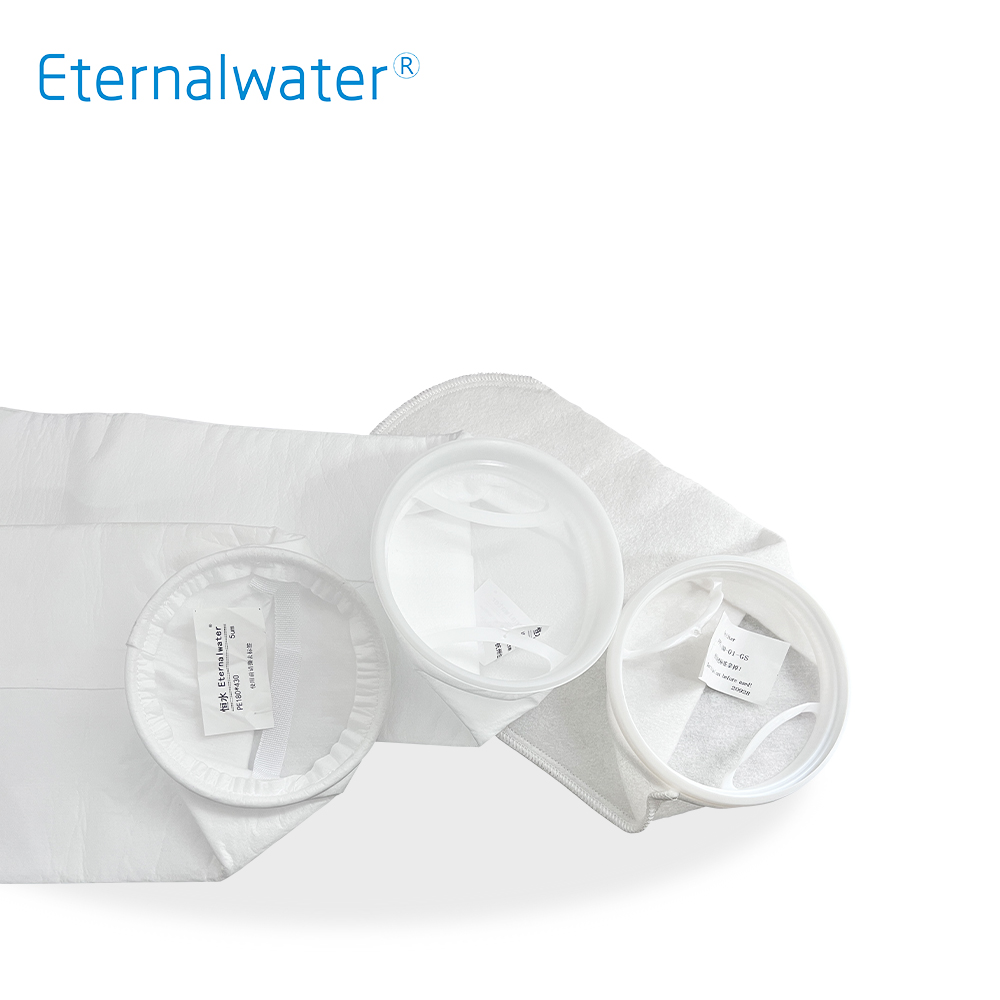

- Industry Application

- Life Sciences

- water treatment

- Industrial Filtration

- Food & Beverage

- Microelectronics

- Laboratory

- New energy battery

- Contact Us

- [email protected]

- +86-571-87022016

- +86-571-87293027

- +8613675899519

- Subscribe for Join Us!

- Join us and get detail information,technical parameter and new products etc.

CopyRight © Hangzhou Eternalwater Filtration Equipment Co., Ltd. 2002-2025

- [email protected]

- Jenny wu

- +8613675899519

- +86(571) 87022016

EN

EN  ES

ES AR

AR JP

JP CN

CN